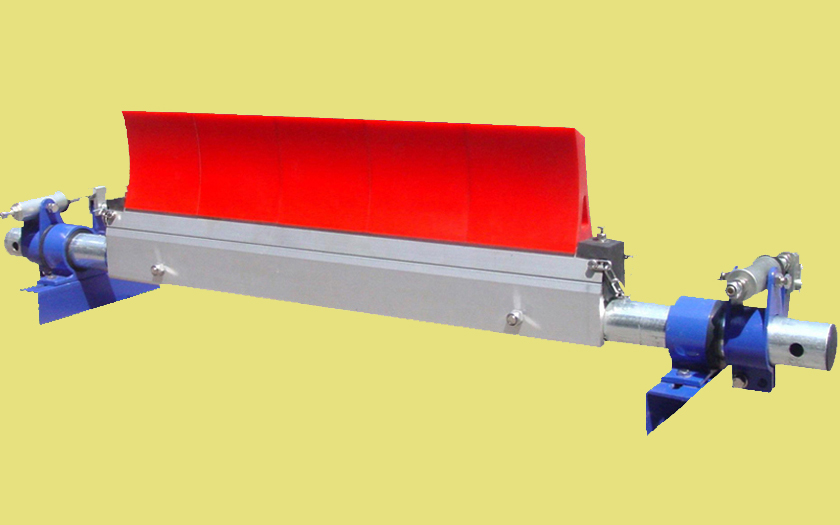

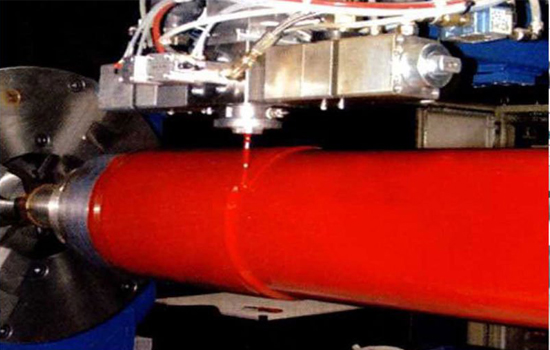

AT SWAGATH latest technology is used for polyurethane covering of various rollers up to 6m in length and 2m in diameter. this method is called rotational casting or ribbon flow molding, production of covered rollers at the minimum time with best surface quality are possible. these rollers with various dimensions and different kinds of flat ribbed are used in all industries such as steel, iron, aluminum, wood and textile.

POLY-PRO Slip-On Roll Covers are made of durable Polyurethane materials in several durometers. They are designed to fit on the O.D. of standard size Conveyor rollers, providing a cushioned, wear resistant, quieter system. They protect the products from damages. They are non-marking. Standard hardness's are 95A orange, 85A White (FDA), 60A yellow, 40A Green. These compounds are Castable type polyurethane, and are more durable than other types of Extruded Polyurethanes. Installation of these rollers is very simple. The I.D of these tubes are made to be slightly smaller than the O.D. of the metal Rollers, so as to provide a press-fit. By lubricating the O.D. of the rollers with a water soluble oil or a soap solution, these tubes are pushed on to the rollers from one end. A Special installation tool is available, that will fit on one end of the tube with a hose clamp, and by blowing air on this end, the tube will enlarge in size to make it easy to slide the tube along the length of the roller. For using this tool, the sleeves are to be 2" longer than the roller, and one end is trimmed with a razor after installation.

Rollers and wheels:

At swagath company the latest technology is used for polyurethane covering of various. Rollers up to 6m in length and 2m in diameter.This method is called rotational casting or ribbon flow moulding. Production of covered rollers at the minimum time with best surface quality are possible.These rollers with various dimensions and different kinds of flat ribbed are used in all industries such as steel, iron, aluminum, wood and textile.

=>For Detailed Specifications on rollers Click Below :

- 1. Concave rollers

- 2. Converting rollers

- 3. Convex rollers

- 4. Conveyor rollers

- 5. Drive rollers

- 6. Feed rollers

- 7.Folding rollers

- 8. Friction rollers

- 9. Idler rollers

- 10. Index rollers

- 11. Inserting rollers

- 12. Laminating rollers

- 13. Load rollers

- 14. Material handling rollers

- 15. Nip rollers

- 16. Packaging rollers

- 17. Pinch rollers

- 18. Pull rollers

- 19. Sealing rollers

- 20. Sortation rollers

- 21. Track rollers

- 22. Transfer rollers

- 23. V-groove rollers

- 24. Web handling rollers

- =>For more details visit www.polyurethanerollers.info

=>For Detailed Specifications on rollers Click Below :

- 1. Concave rollers

- 2. Converting rollers

- 3. Convex rollers

- 4. Conveyor rollers

- 5. Drive rollers

- 6. Feed rollers

- 7.Folding rollers

- 8. Friction rollers

- 9. Idler rollers

- 10. Index rollers

- 11. Inserting rollers

- 12. Laminating rollers

- 13. Load rollers

- 14. Material handling rollers

- 15. Nip rollers

- 16. Packaging rollers

- 17. Pinch rollers

- 18. Pull rollers

=>For more details visit www.purollers.com

Pallet trucks.

Stackers.

Manipulators.

Fork lift tyres.

Fricition wheels.

Roller skate wheels.

Wagon wheels.

Rotators.

Small bearings.

- Features:

low wear and tear.

High load bearing capacity.

Low rolling resistance.

Non-marking.

Resistant to oil, grease & chemicals.

Wide temperature stability(-40c to 80c)

Strong bonding with various insert materials.

Typically, wheels are made of a thin coating of polyurethane of any hardness, bonded to metal hubs. Typical applications of wheels are used for escalators and elevators.