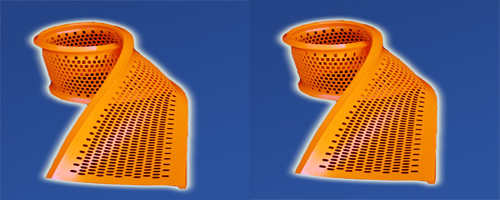

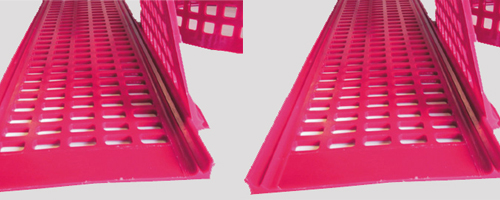

Polyurethane Flip Flop Screen Mats

Flip flop or flip flow screening machines have been in operation for decades for screening of moist or humid materials. Some typical applications

Iron Ore at 6mm with 15% moisture

· Raw sand at 3mm with 6% moisture

· Compost at 10mm with 50% moisture

· Slag at 3mm with 10% moisture

· Salt at 3 mm with 5 % moisture

· Coke at 3mm with 20% moisture

· Lignite at 6mm with 50% moisture

· Coal at 6mm with 18% moisture

· Limestone at 3mm with 20% moisture

· Pet coke at 3mm with 18% moisture

· Plus other hard to screen materials like wood chips, bamboo chips, washery waste, building rubble, soil, plastic, auto parts etc.

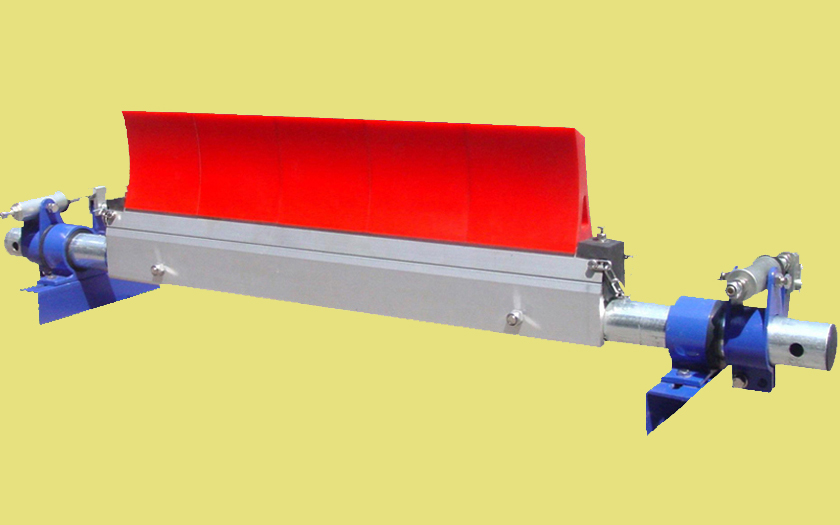

Principle of Operation :

Generally referred to as “flip flow” or “ flip flop” screening method. During the cycling of screener, the flexible mats are individually tensioned and relaxed, which breaks or loosens the adhesive bond within the materials, and between the material and flip flow screen mats.

In the upstroke, the material is impelled upward functioning like a trampoline and air is drawn in and through the material.

The motion is such that the acceleration on machine support frame could be approx 3g whereas the material on the screen panels may experience around 50g.

During these stretch & relax moments, the openings or aperture in the screen mats get elongated , stretched or bend which tremendously helps in release of particles which might have got jammed.