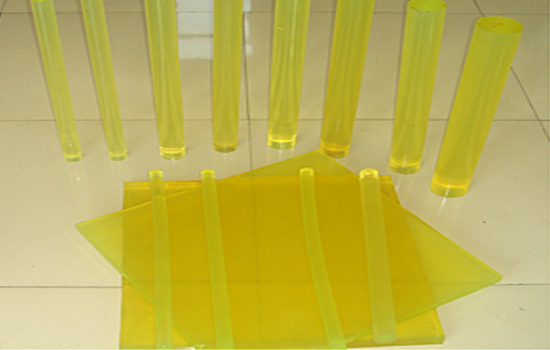

Polyurethane Sheets / Rods

Polyurethane (PUR and PU) sheet is any polymer composed of a chain of organic units joined by carbamate (urethane) links.

Polyurethane (PUR and PU) sheet is any polymer composed of a chain of organic units joined by carbamate (urethane) links.

Polyurethane polymers are formed through step-growth polymerization, by reacting a monomer (with at least two isocyanate functional groups) with another monomer (with at least two hydroxyl or alcohol groups) in the presence of a catalyst.

Polyurethane sheet are applied to the manufacture of flexible, high-resilience foam seating; rigid foam insulation panels; microcellular foam seals and gaskets; durable elastomeric wheels and tires; automotive suspension bushings; electrical potting compounds; high performance adhesives; surface coatings and surface sealants; synthetic fibers (e.g. Spandex); carpet underlay; and hard-plastic parts (i.e. for electronic instruments).

Moreover, polyurethane products often are inaccurately called “urethanes”, but must not be confused with urethane proper (ethyl carbamate), because polyurethanes neither contain nor are produced from ethyl carbamate.

- =>For Detailed Specifications on PU Sheets/Roads Click Below :

=>For more details visit

Polyurethane Sheet with very good chemical erode resistant, impregnant resistant, ozone resistant, radiation resistant, aging resistant, hydrolyze resistant. And high tear resistant, high impact resistant, high bend strength and low compression set etc.

The abrasion resistant is 5 multiple more than pure natural rubber, and the oil resistant is 3-5 multiple more than NBR rubber, and have high elasticity 65% with prominent compression resistant at high temperature. With broad hardness range on 15-98 Shore A, very good viscidity with metal material, Polyurethane sheet is a new macromolecule material with fast evolutive now.

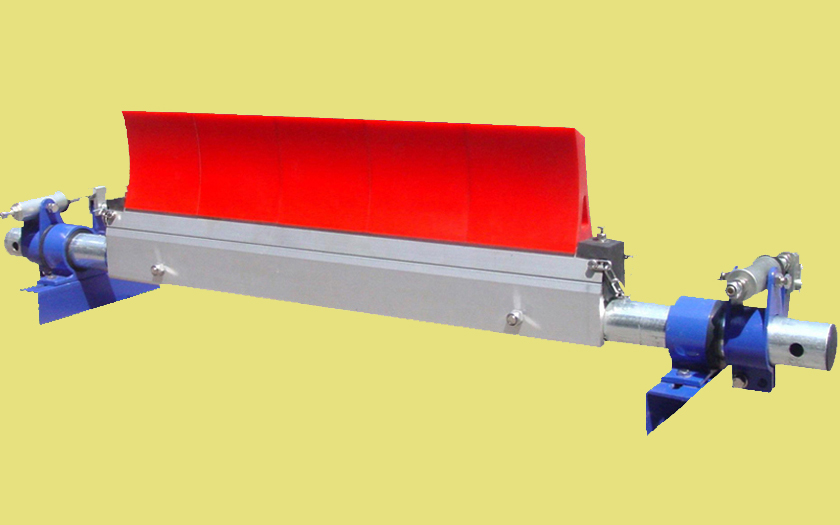

Apply to military, mine, oil field, chemical, printing, punch, paper making, Shoe making, spin, auto etc industrial.